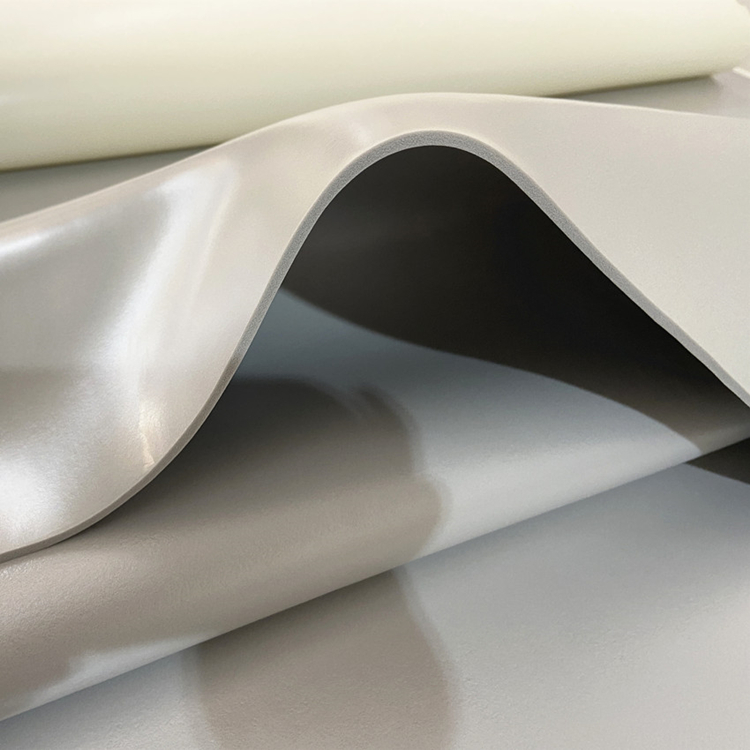

Product Description

Hollyseal® low and medium density foam is a soft, closed-cell PVC foam that provides excellent sealing against water, dust, light and other substances at various compression levels, and also provides cushioning and shock absorption during the installation of structural components. The surface of the foam can be protected with self-adhesive pressure-sensitive adhesive, paper or release film according to the needs of use. In addition, the density (180±20 kg/m³), thickness (1-25 mm), hardness, and compression rebound of the foam can be adjusted to provide performance for a variety of applications. It is suitable for various applications such as automotive sheet metal vibration damping sealing, water tank sealing, HVAC sealing, door and window roof weather stripping, electrical and electronic vibration damping sealing, power battery sealing and cushioning, die-cutting gaskets, etc. for dustproof, waterproof, vibration damping, cushioning, sound insulation, heat insulation, etc.

Product Features

1. Foam can play an excellent role in sealing water, dust, light and other substances after 30% compression

2. Excellent shock absorption and sound insulation performance

3. Excellent anti-UV performance and weather resistance

4. Good thermal insulation performance

5. Good resistance to acid and alkali

6. Wide range of use temperature

7. Flame retardant grade can be customized (UL-94-V-0 class/ BS476:part7:1997 ClassⅠ)

Product Application

1.Car body vibration damping 2.Door and window roof weather stripping 3.HVAC sealing 4.Electrical sealing 5.Freezer sealing

6.Electronic equipment sealing 7.Mechanical housing sealing 8.Outdoor lighting fixtures

Technical Information

| Density | 180±20kg/m3 |

| Flame retardant | UL-94 V-0 |

| Tensile strength | ≥350kPa |

| Elongation at break | ≥150% |

| 90° Peel strength | ≥2N/10mm |

| 25% Strain compression | ≥0.2kg/cm2 |