Product Description

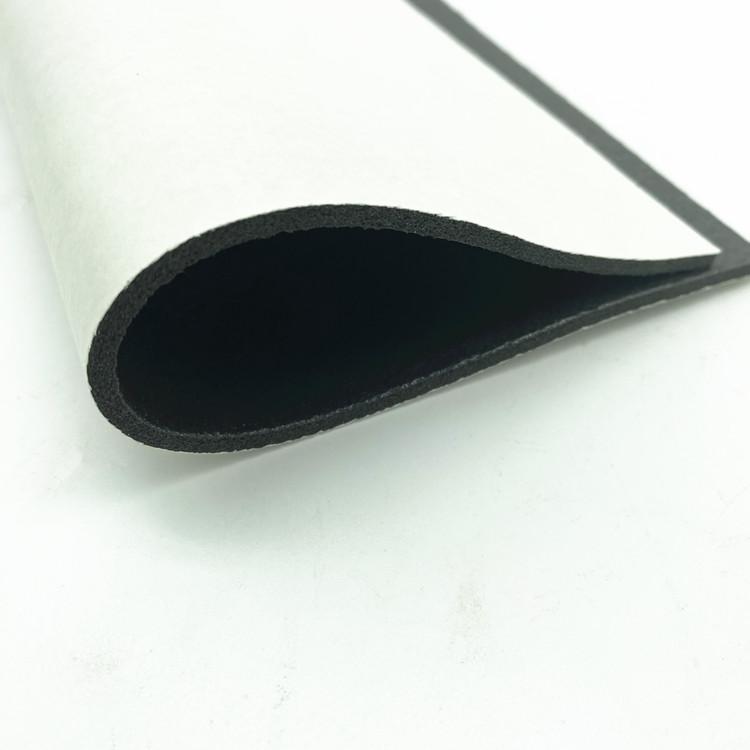

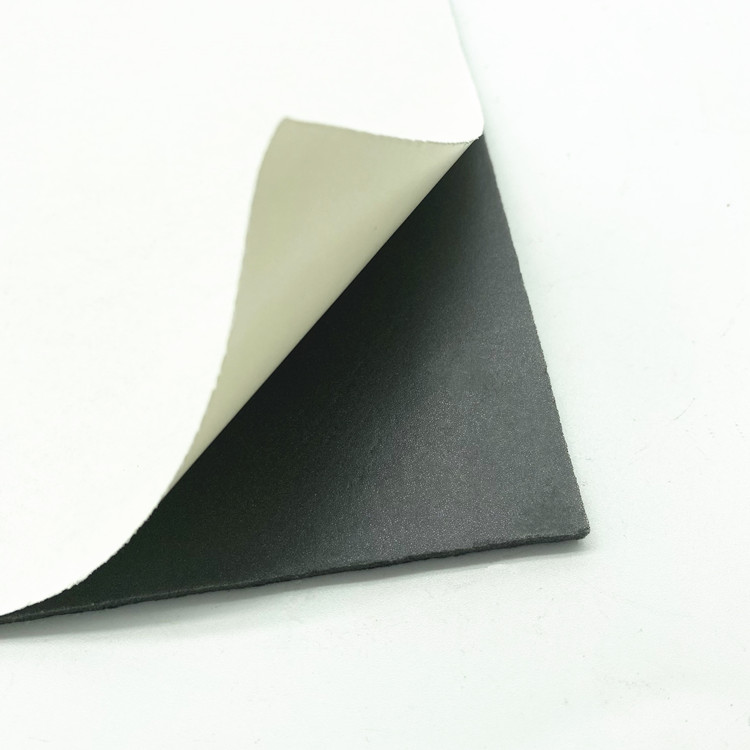

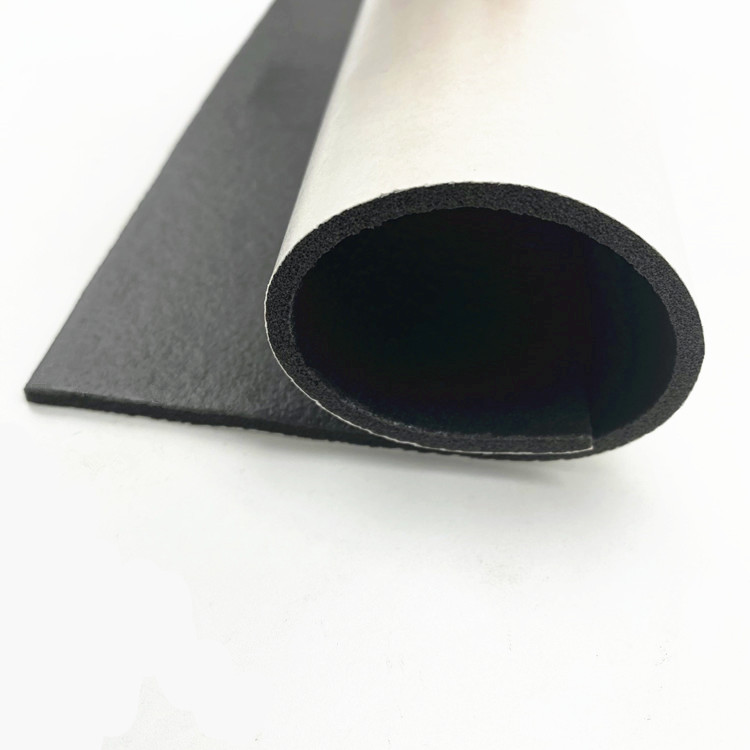

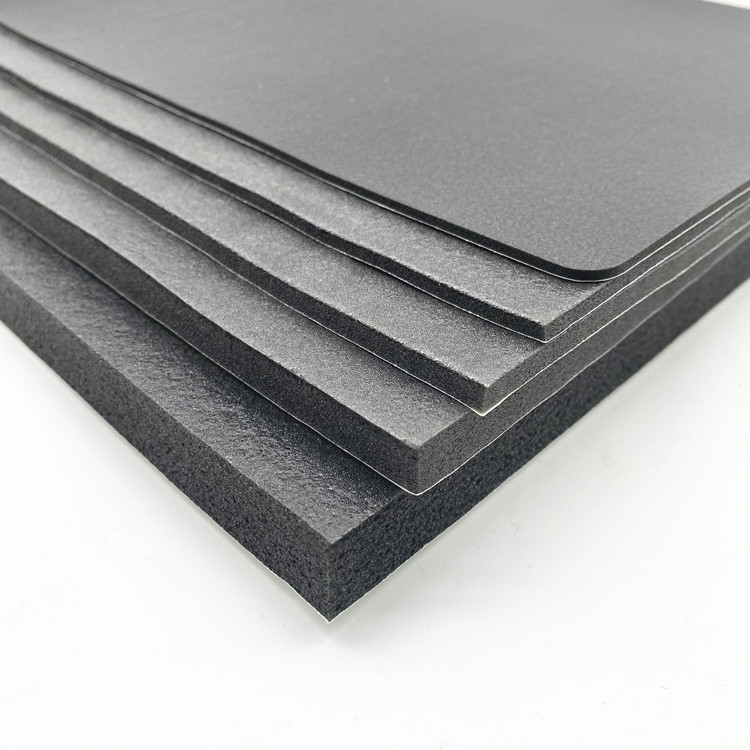

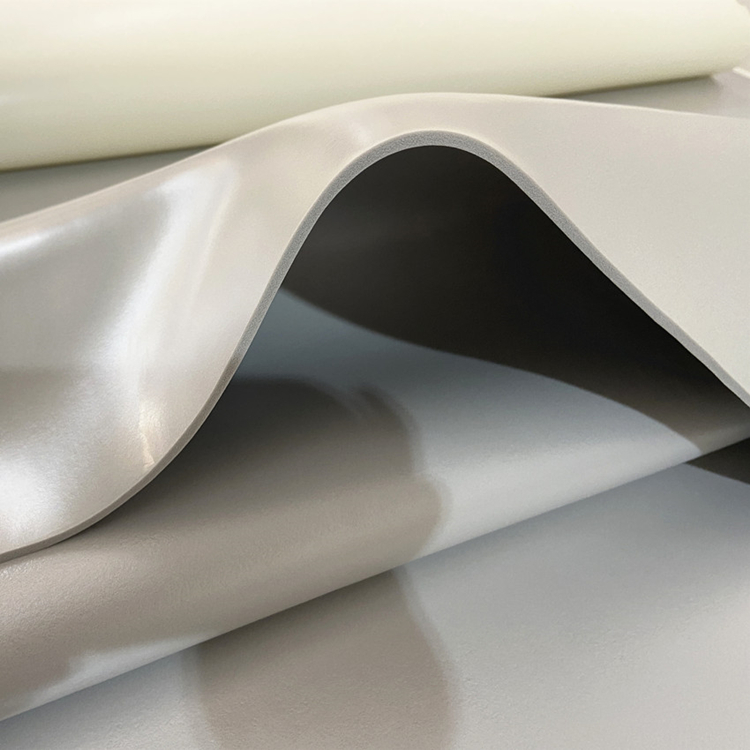

Hollyseal®Low density foam is a soft, closed-cell PVC foam that provides excellent sealing against water, dust, light and other substances at various compression levels, and also provides cushioning and shock absorption when structural components are installed. The surface of the foam can be protected with self-adhesive pressure-sensitive adhesive, paper or release film according to the needs of use. In addition, the density (130±20kg/m³), thickness (0.5-25mm), hardness, and compression rebound of the foam can be adjusted to provide performance for various application scenarios. Suitable for various applications such as automotive sheet metal vibration damping sealing, water tank sealing, HVAC sealing, door and window weather stripping, electrical and electronic vibration damping sealing, power battery sealing and cushioning, die-cutting gaskets, etc. for dustproof, waterproof, vibration damping, cushioning, sound insulation, heat insulation, etc.

The main types of PVC foam we produce, they are.

● Fast recovery foam - material recovers immediately after compression

● Slow recovery PVC foam - ideal for filling irregular surfaces

Product Features

●Excellent vibration and sound damping performance

●Good compression rebound and adhesion

●Highly conformable to curves and irregular shapes

●Excellent UV resistance and weather resistance

●Sealing water, dust and air can be achieved at 30% compression

●Release paper on non-adhesive surface reduces dimensional changes during application

●Flame retardant rating can be customized (UL94 V-0; BS476:Part7:1997 Class1)

Product Application

1.Door and window roof weather stripping

2.Car body shock absorption

3.HVAC sealing

4.Electrical sealing

5.Refrigerator sealing

6.Electronic equipment sealing

7.Mechanical housing sealing

8.Outdoor lighting fixtures

Technical Information

| Density | 130±20 kg/m3 |

| Tensile strength | ≥300kPa |

| 30% permanent compression deformation | ≤4% |

| Hardness(Shore 00) | 15±5° |

| Elongation at break | ≥130% |

| Flame retardant | UL94 (HBF/HF-1/V-0 ) FMVSS 302 The above series can be customized |